Ball bearings

The ball bearings are the most common and the most utilized applications on the market, being able to withstand axial and radial loads. Its main feature is the rotation speed, being higher than in other types of bearings.

Fersa has the following ball bearing types:

- Radial ball bearings: The single row ball bearing is the most popular of this family, because it is involved in many applications.

- Angular contact ball bearings: Fersa is mainly into the double row ball bearing spectrum being used by leading automobile manufacturers.

- Thrust ball bearings: We have them in the clutch bearing catalog.

Deep groove ball bearings

The deep groove ball bearings are composed of an inner and an outer ring as well as a cage with a precision ball set.

These bearings are mainly designed to support radial and axial loads from any direction and allow operation at a relatively high speed.

The technical dimensions conform with the ISO 15 Standard. In addition, they comply with the snap ring groove dimensions specified in the ISO 464 Standard.

Special ball bearings

Fersa manufactures special ball roller bearings serving the need for certain applications and are recorded under the nomenclature F 18000.

The most popular applications for this bearing type are the gearboxes for different types of vehicles.

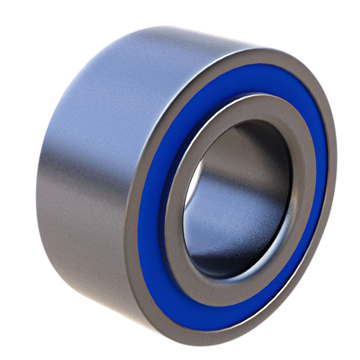

Special angular contact double row

The double row angular contact ball bearings can bear large radial loads in both directions since the line of action for the loads form an angle at the bearing axle.

This family is identified under the nomenclature F 16000.

The main application of this typology is for light vehicle wheels, therefore we rely on special references whose outer ring has incorporated design changes to improve its integration with the final application.

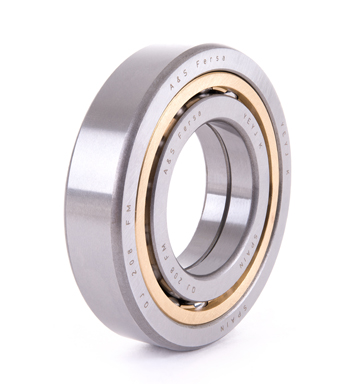

Standard angular contact double row

Angular contact ball bearings have a fundamental feature where the load line of action between the balls and the rolling tracks forms an angle with the geometric bearing axle. For this reason, the rolling tracks of the inner and outer rings are axially offset from each other, allowing endurance of large radial loads in both directions.

Four point angular contact

Four point angular contact ball bearings are composed of a single radial row and have been designed to support axial loads in both directions.

The radial load can be adapted to a certain axial load level. Since these bearings require less axial space, they are a very attractive choice if you have limited space.

Air Conditioning Bearings

They are double row ball bearings designed to operate at high rotational speeds and low noise, technically different by being composed of a single inner ring. They are within the nomenclature F 16000.

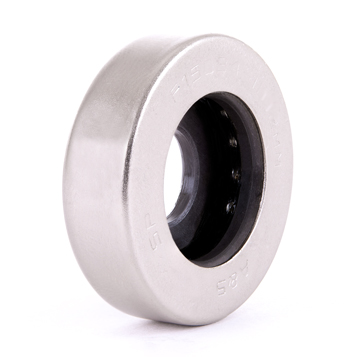

Thrust ball bearings

Thrust ball bearings can support large axial loads in one direction, requiring a minimum axial load for optimum performance.

The bearings are detachable so that the assembly is simple since the washer, the ball, and the cage can be mounted separately.

Clutch release bearings

Clutch release bearings are self-aligning types of bearings. They are designed to control certain clutch conditions associated with the misalignment of components.

The bearings run against the clutch spring to connect-disconnect the engine from the transmission and control the conductor to operate the clutch pedal.