The smart solution

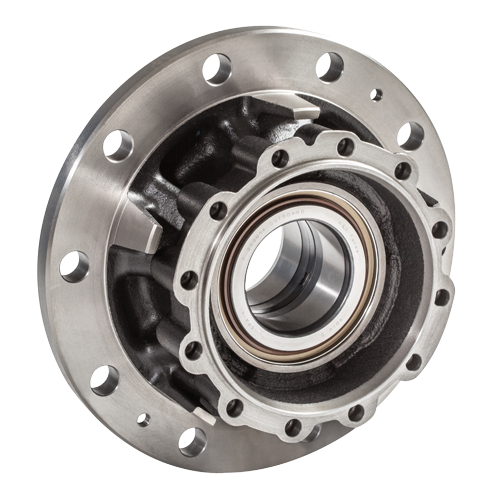

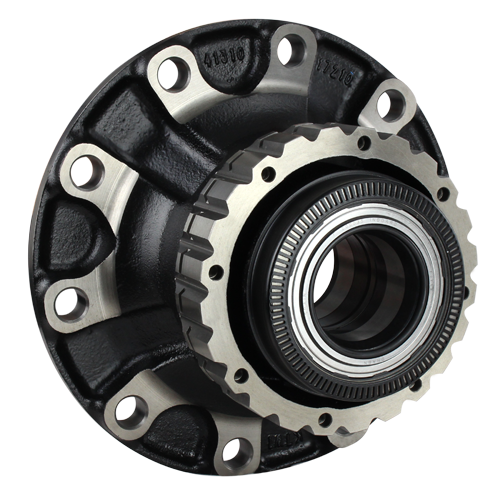

Wheel Hub Assembly

We are the first and only bearing manufacturer that has its own developed hubs.

We have the ideal bearing for each hub. We work with restricted tolerances to ensure optimal operation.

We are backed by our experience as suppliers of hub units for first-class vehicle manufacturers.

We know and respect the requirements of the original equipment and apply them to all products in our range.

Accurate and safe design

Our engineers are involved from the design of the hubs and the choice of raw material to the after-sales service.

We provide materials and designs which are original counterparts. We respect tolerances and clearances and validate each of the pieces with a final application.

The surfaces of our hubs are mechanized with a high degree of precision and we guarantee the high quality of the raw material.

We carry out tests demonstrating optimum performance on both on our own benches and on the field.

Intelligent production process

Our manufacturing lines incorporate the latest technologies in terms of quality control. Our systems collect and track more than 200 records for each bearing, both dimensional and functional.

We have a high level of automation to improve the quality and competitiveness of our products. Our manufacturing lines collect information in real-time, which allows us to adjust parameters and detect possible failures automatically.

We have a production capacity of more than 60,000 wheel hub assemblies per year.